RACING, ELEVATED.

True performance on an Aston Martin starts with precision. We don’t just sell parts. Each kit is built around exacting fitment, rigorous verification, and a deep understanding of the architectures. Whether you’re restoring a DB11, upgrading a Vantage, pushing the limits of a DB12. Performance is reborn here.

-

transmission

Regular price €0,00Regular price

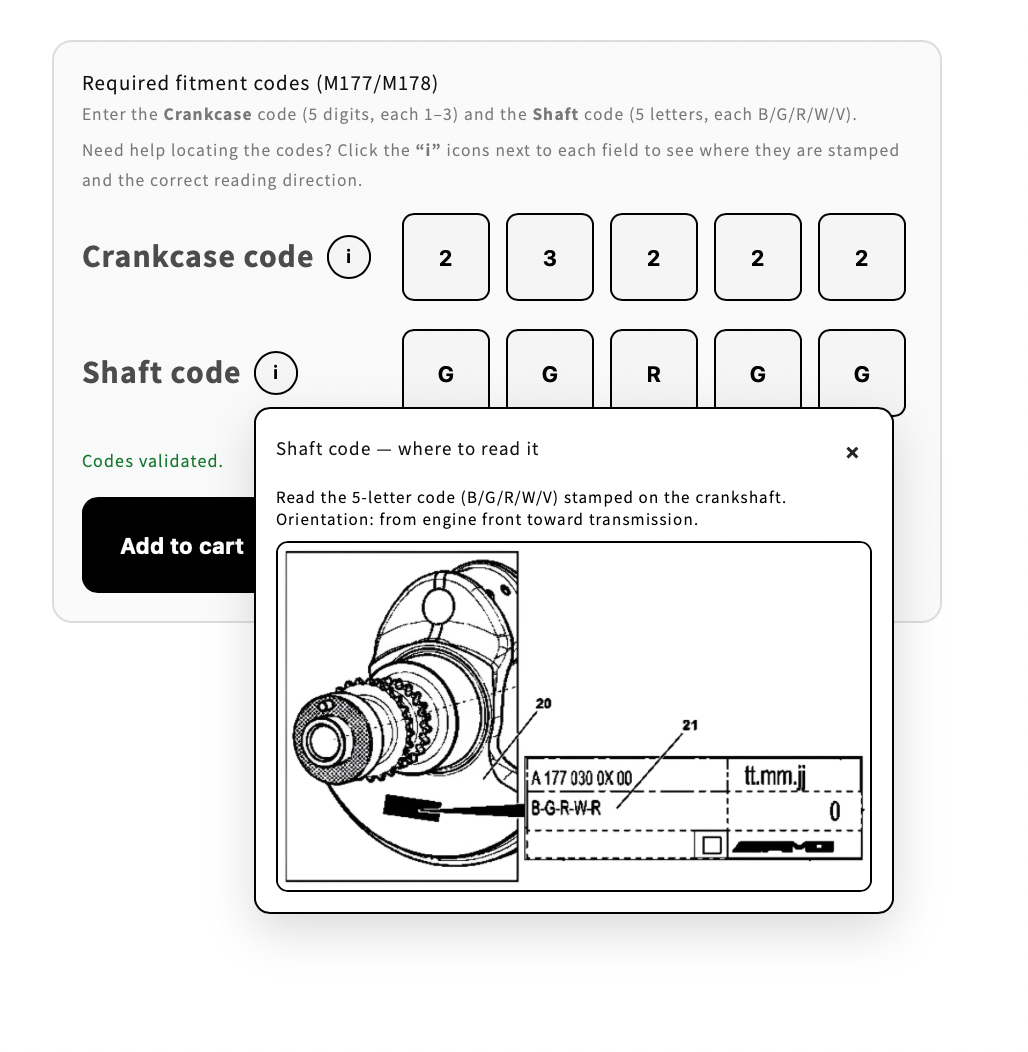

OEM-Coded Ordering System for M177 / M178

Engine bearing kits built onyour exact crankcase and crankshaft codes.

No errors. No compromises. 100% verified fitment.

Validated by Precision

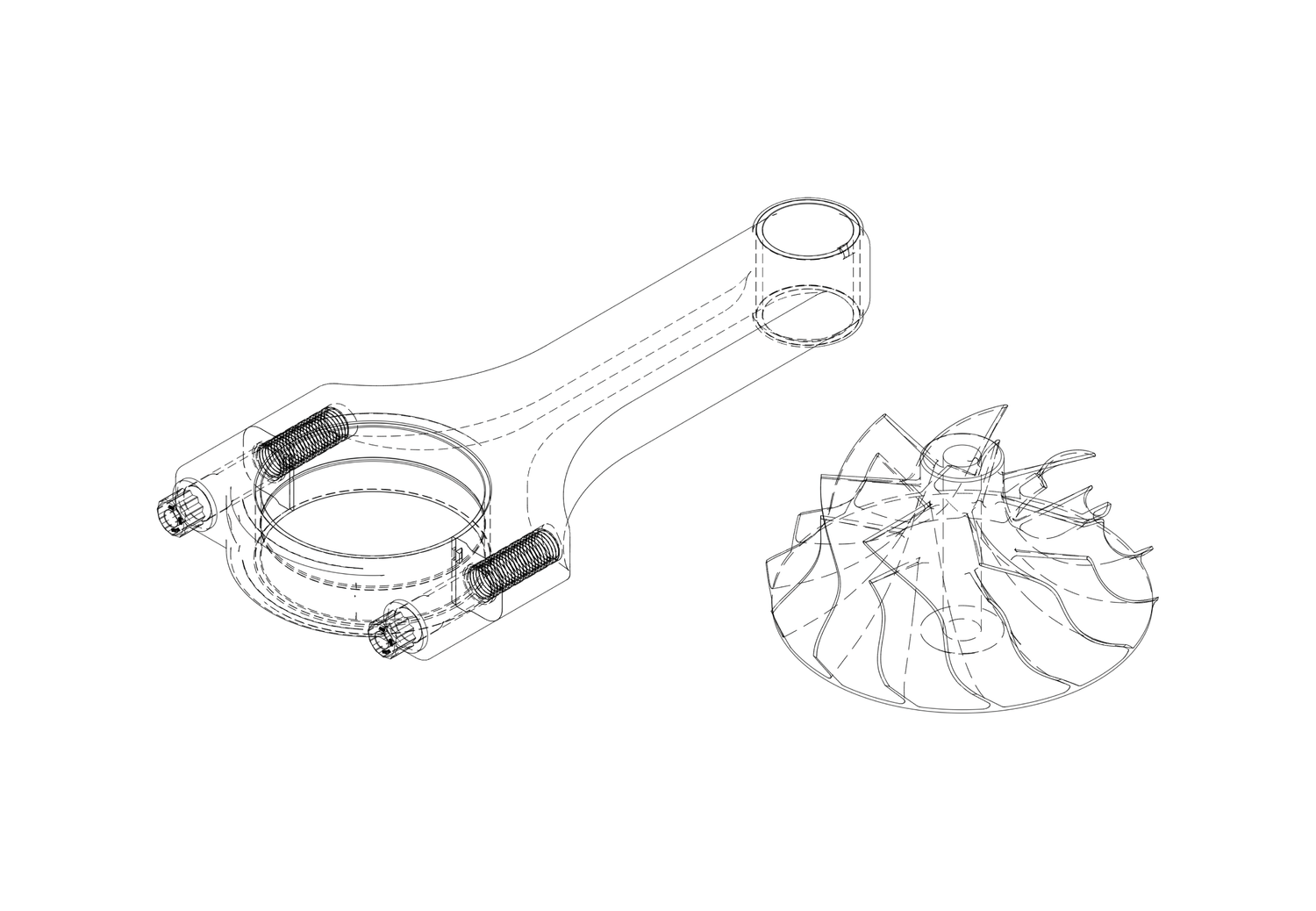

True engineering excellence begins with precise calibration. At Standbury, every component is validated, ensuring micron-level accuracy across the entire engine. By relying on calibrated instruments of the highest standard, we guarantee that each rod, impeller, and assembly delivers perfect fitment, balance, and reliability under extreme conditions.

Engineering the Core of Performance

Every Standbury component begins as a digital model, engineered with precision and validated through advanced simulations. From forged connecting rods to CNC-machined compressor impellers, our design process ensures maximum strength, balance, and reliability under extreme conditions.

Our Commitment to Excellence

Innovation & R&D

At Standbury, innovation is not an option — it is our foundation.

Our R&D team leverages advanced CAD modeling, finite element analysis, and fluid dynamic simulations to engineer components that maximize performance while ensuring reliability under extreme conditions. Each concept undergoes iterative prototyping, material testing, and validation on real vehicles. This relentless pursuit of excellence allows us to deliver solutions that not only enhance performance, but redefine what precision engineering can achieve.

Quality & Certifications

At Standbury, quality is not a claim — it is a system.

Our processes are structured around internationally recognized standards to guarantee consistency, safety, and traceability across every stage of development and production.

- ISO 9001 – Quality Management: our workflows are aligned with ISO 9001 principles, ensuring full process control, documentation, and continuous improvement.

- ISO 26262 – Functional Safety: for ECU calibration and electronic systems, we follow ISO 26262 guidelines to ensure reliability and compliance with automotive safety frameworks.

- IATF 16949 – Automotive Quality: our production partners operate under IATF 16949 requirements, the global benchmark for automotive suppliers.

- IMI Certified Technicians: our tuning and remapping specialists hold IMI credentials, confirming technical competence in ECU programming and repair.

This combination of global standards and certified expertise provides the assurance that every Standbury component is engineered, tested, and supported with the same rigor demanded by world-class automotive manufacturers.

Manufacturing Process

Engineering precision demands uncompromising production methods:

- Premium alloys & aerospace-grade treatments ensure unmatched strength-to-weight ratio.

- 5-axis CNC machining achieves tolerances below 10 microns (<0.01 mm).

- Surface finishing & heat treatments improve fatigue resistance and component longevity.

- Comprehensive validation includes vibration, stress, and thermal cycling tests in addition to dyno and road verification.

This meticulous process results in components that consistently outperform OEM specifications, offering measurable gains in both performance and durability.

Warranty & Support

Our responsibility extends beyond the purchase.

Every Standbury component is covered by a comprehensive 2-year warranty against manufacturing defects, supported by a dedicated technical team available worldwide. Our aftersales support includes installation guidance, real-time troubleshooting, expedited replacement logistics, and personalized customer care.

We understand that precision parts demand precision service — and our support infrastructure is designed to provide peace of mind equal to the quality of our products.

Compatibility & Installation

All Standbury components are designed for a seamless fit with M177/M178 platforms. Installation guides are engineered to simplify workshop integration, with detailed torque specifications, calibration notes, and diagnostic insights.

We maintain a global partner network of certified workshops trained in high-performance component installation, ensuring each part is fitted to the same standards with which it was built. From delivery to road test, compatibility and precision are guaranteed.

Responsibility & Sustainability

Excellence also means accountability.

Standbury is committed to reducing its environmental footprint by implementing lean manufacturing, minimizing waste streams, and incorporating recyclable materials wherever feasible. Our facilities are progressively powered by renewable energy sources, while packaging is designed with minimal environmental impact in mind.

We believe that high performance and sustainability must coexist — building not only components for today’s drivers, but a future where engineering and responsibility are inseparable.